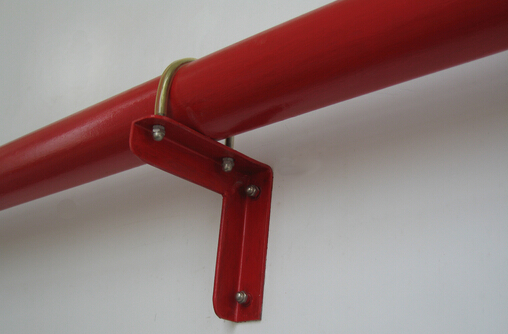

Pipe hangers play a role in supporting weight and maintaining spatial location of

pipelines, and have influences on cold and hot deformation and stress of various parts. Therefore, we should pay attention to the installation of pipe hangers.

1. There is often a fixed bearing set in the pipe, which has the greatest force. Besides part of the pipe’s weight, it also has to withstand the thrust, tension and torsion of pipeline when expansion and contraction. Bracket and clamp of fixed bearing should be in close contact with the pipe wall, letting the tube not rotate or move. The hanger between two fixed bearings should not hinder pipe’s movement caused by changing temperature and weight.

2. Hangers are generally used for horizontal pipe. Base plate (tube pillow) at bottom should be firmly connected with the pipe, so that it can move with the pipe. The sliding surface between base plate and lower support surface (platen) must be parallel, smooth, good contact and without hindrance. If you place a roller between them, it should also have good contact and flexible scroll.

3. Spring hangers are generally used for pipes with large hot and cold difference and with several directions towards thermal placement. Specifications and compression springs must be consistent with the construction plans. The spring should be kept straight, not curved. There should be a sufficient distance between the spring and the wall for heat preservation. During the installation of a hanger and under cold state, it should be inclined toward the direction opposite to that of thermal state. The inclination angles of two states should be the same. The cantilevers that supporting hangers should be packed horizontally and the root structure must be firmly.

4. If there is a large thermal displacement in high temperature and pressure pipeline, it should adopt a constant force hanger because the carrying capacity of constant force hangers does not change with the place of the lifting point. Therefore, when the pipe has thermal displacement, there won’t be reallocating of load for each lifting point of

pipe system. As a result, the pipe system will not cause additional stress.

5. When determining the position of each hanger, you should take the displacement that occurred between hot and cold states into account. Formally install the fixed bearing before

cold drawn processing and preliminary install the rest hangers. Further adjust them after cold drawn processing. Adjust individual positions again after running hot state. Since the work status assumed in construction plans is not necessarily correspond with the actual status, it is required to inspect under running and correct according to the actual situation.

Download Steel Pipe Fitting PDF

Download Steel Pipe Fitting PDF Download Steel Pipe PDF

Download Steel Pipe PDF Download Steel Flange PDF

Download Steel Flange PDF